1. Introduction

This paper describes the Simio modeling system that provides a simulation modeling framework based on intelligent objects to optimize both the design and operation of complex systems. Historically, simulation tools have focused on system design, however, Simio was designed from the ground up with a focus on both system design and system operation. This required a paradigm shift in how models are designed and used and was the driving force behind Simio’s unique modeling architecture.

In the past few years, the term “Digital Twin” has become popular in describing the use of a simulation model that is connected to real time data and employed in an operational setting. While many tools position themselves as a process Digital Twin, there are significant challenges in implementation, and legacy simulation tools are not designed to address these challenges. In this paper the focus will be on the unique Simio features that address these challenges to support the creation of an Intelligent Adaptive Process Digital Twin as shown in the graphic below.

Figure 1: The Simio Intelligent Adaptive Process Digital Twin

The following figure summarizes the distinction between a Digital Shadow, a Virtual Model, and a Digital Twin. In the case of a Digital Shadow, there is no simulation model of the system, but automated data collection is in place and analytics such as statistical regression or AI can be applied to identify patterns and predict events such as a machine breakdown, allowing problems to be addressed before they occur. This only works when there are no fundamental changes to the system since historical data is being used to predict the future. In the case of a Virtual Model, a simulation model of the system that can be manually fed with representative data and executed offline is built. This facilitates analysis of design decisions such as the purchase of new equipment or the introduction of a new product. Unlike the Digital Shadow, the Virtual Model is forward-looking and allows analysis of the impact of changes on the system. This has been the traditional use of simulation modeling over the decades. In the case of the Digital Twin, the simulation model is extended to daily operations by directly connecting the model to the real-time system status. This allows for the simulation to look forward in time to visualize and fix operational issues in the real system, such as tardy orders, before they occur.

Figure 2: Digital Transformation Scenarios

With Simio, the focus is on the use of a simulation model as a Virtual Model for system design, as well as the extension of that model to provide a process Digital Twin. Many organizations are driving a digital transformation agenda that includes both traditional design applications using a Virtual Model, as well as the operational use of the model in planning and scheduling. Depending on the digital maturity of the organization, users may be at different points along the digital transformation journey as depicted below.

Many organizations are making effective use of a Virtual Model for predicting performance and optimizing system design; however, few organizations have fully mastered the transition to an operational Digital Twin that automatically optimizes daily operations. Even if the intermediate focus is on using a Virtual Model for traditional design simulation applications, Simio provides a rich platform for building and experimenting with design models while also positioning users for expansion into a fully connected Digital Twin in the future. Simio is designed to support the full design-operate continuum.

Figure 3: The Digital Continuum

As users move from the Virtual Model for design to the fully connected Digital Twin for operational use, there are several key challenges that must be addressed:

- Operational models often require complex modeling of resources, materials, and business logic that constrain process flows – otherwise the resulting schedules are not actionable in the real system. This places additional demands on the modeling logic and flexibility compared to traditional design applications.

- The model must be data centric, where both the structure of the model and the data for the model are defined in external data sources. The data should be easily accessed with direct connections to the ERP, MES, IoT, Web Services, etc. The model data must also be held in memory for fast execution.

- Traditional simulation tools provide summary statistics, however operational models require detailed reporting that traces individual jobs, resources, materials, etc., and displays the results in web-enabled Gantt charts and dashboards that are custom designed and tailored to different stakeholders.

- Many traditional simulation design tools are designed for use on the desktop, whereas a process Digital Twin can be deployed across the enterprise on a private or public cloud.

- The decision logic that is embedded in the simulation model drives the performance of the system. It’s critical that the modeling tool supports advanced decision logic that may include Machine Learning algorithms for managing the workflow and optimizing the schedule.

- A Digital Twin generated production schedule must use deterministic processing times and eliminate random events such as breakdowns. However, this results in an overly optimistic schedule that typically degrades as unexpected events occur in the real system. Therefore, a mechanism is required to assess the risk of a Digital Twin-generated deterministic schedule by using randomness in the risk assessment.

Although many of these functional requirements are essential for Digital Twin applications, they are also very useful in traditional design applications. In the following sections, Simio’s unique approach to addressing these key challenges is described.

2. Object Framework for Complex Modeling

Simio is a simulation modeling framework based on libraries of intelligent objects. A beginning modeler may prefer to use pre-built objects from Simio libraries; however, the system is designed to make it easy for even beginning modelers to build their own intelligent objects for use in building hierarchical models. Custom intelligent objects can be built by modelers and then reused in multiple modeling projects. These objects can be stored in libraries and easily shared. The flexibility and ease of building custom objects is critical to building Digital Twin models that can be quickly adapted to complex applications and is a key advantage of Simio over legacy simulation products.

A Simio object could depict a machine, robot, airplane, customer, doctor, tank, bus, ship, or any other item that might be encountered in a system. A model is built by combining objects that represent the physical components of the system. An object is animated in 3D to reflect the changing state of the object. For example, a forklift raises and lowers its lift, a worker walks to a location or carries items between locations, and a robot opens and closes its gripper. The animated 3D model provides a moving picture of the system in operation. Simio’s detailed 3D, GIS, and VR features (using the Oculus headset) provide a powerful visualization of the process to validate model behavior and showcase capability.

Figure 4: Simio Digital Twin Animation View

Objects in Simio are built using object-oriented concepts. However, unlike other object-oriented simulation systems, the process of building an object in Simio is simple and completely graphical. There is no need to write programming code to create new objects. The activity of building an object in Simio is identical to the activity of building a model – in fact there is no difference between an object and a model. This concept is referred to as the equivalence principle and is central to the design of Simio. Whenever a user builds a model, it is an object that can be instantiated into another model. For example, if two machines and a robot are combined into a model of a work cell, the work cell model is itself an object that can then be placed any number of times into other models. The work cell is an object just like machines and robots are objects. Every model that is built in Simio is automatically a building block that can be used in building higher level models.

The Simio object framework is built on the same basic principles as object-oriented programming (OOP) languages; however, these principles are applied within a modeling, not a programming, framework. Simio is not simply a set of classes available in an OOP language, such as Java or C++ that are useful for building simulation models. Simio is a code-free graphical modeling framework, designed around basic object-oriented principles, to support the construction of simulation models. For example, when an object such as a “machine” is created in Simio, the principle of inheritance allows the creation of a new class of machines that inherits the base behavior of a “machine”, but this behavior can be modified (overridden) and extended. Whereas in a programming language, behavior can be extended or overridden by writing methods in a programming language, in Simio, object behavior is changed by adding and/or modifying graphically defined process models. With Simio, the skills required to define and add new objects to the system are modeling skills, not programming skills.

Simio’s object-oriented modeling framework makes it easy to create application templates that jump-start model creation. A template is a library of custom-built objects along with data schemas and custom reports that are focused on a specific application area. Simio provides templates for modeling common discrete and batch manufacturing processes and warehouses and users can expand on those objects and/or create their own objects and templates for use within their enterprise.

Simio’s core set of modeling features for defining object behavior, along with the graphical object-oriented design of Simio is key to making it easy to create custom-made objects targeted at specific applications. Simio has advanced modeling features for capturing complex resources, as well as material and business logic constraints in typical production, warehousing, and delivery systems. For example, any processing delay can be directly modeled as an action network of parallel and/or sequential tasks, each requiring its own set of materials and resources. Each task in the action network can also have a sequence dependent processing time based on multiple attributes such as color, size, etc., and task times can be adjusted based on learning curves for the workers assigned to the task. Likewise, vehicle movements within a warehouse can employ Simio’s fleet management features to automatically plan travel and avoid deadlocks on bidirectional paths across the transportation network.

One important new modeling capability recently added to Simio includes features for implementing Demand Driven Material Requirements Planning (DDMRP) for inventory replenishment. Using principles established by the Demand Driven Institute to optimize production, this methodology is important for modeling the optimal placement of inventory both within the factory and across the supply chain. Simio is the only Digital Twin simulation product that is certified as compliant software by the Demand Driven Institute.

3. Data Centric Design

In the past, simulation models were constructed by dragging and dropping objects into a model, and then directly populating the objects with data. For example, a simple model in Simio can be built by graphically placing a Source, Server, and Sink in the Facility view of the model, and entering the interarrival time of the Source, and the processing time of the Server. In a few mouse clicks and keystrokes, a running model of a simple server system is built. A similar approach is used by many simulation products.

Although this approach to modeling is fine for simple models, Simio’s data-centric framework provides a superior option for large models. With more extensive models, it is best practice to use data tables for defining the objects placed in the model. Subsequently, Simio can automatically generate the model based on the provided data description. The data tables specify the objects to be incorporated in the model, along with their associated data values. This approach is particularly useful in applications where multiple similar facilities are being modeled, allowing each model to be defined and managed through data tables. Note that this transforms the problem from a model building activity to a model configuration activity. A new machine can be added to a model by simply adding a new row of data to the appropriate data table.

The term data-generated is used to refer to models that are automatically created from a data set. The term data-driven is used to refer to models that supply their data to the modeling objects using a data set. A model can be data-driven but manually built using drag and drop, or it can be both data-generated and data-driven.

In many cases, the data that drives a model is relational where a row in one table maps to multiple rows in other tables. For example, a table of sales orders might map to multiple rows defining the products that make up the sales order. Simio fully supports relational data tables with key columns and foreign key references. Data sets in Simio have a totally flexible schema and can be fully configured by the modeler. Users can add/delete/edit columns, keys, and foreign key references. The columns in a table are strongly typed and include both numeric and non-numeric values.

The data-generated and data-driven modeling approach is particularly effective when used in combination with a custom application library, which contains pre-defined data tables and objects that are focused on the specific application, along with data mappings to connect to the appropriate table columns that supply the relevant data for the object. A skilled modeler can create an application specific template that is then populated by others to auto-create and maintain their models via data. This is one of the reasons why Simio’s graphical approach for object definitions (no programming) is important to the successful implementation of data-generated and data-driven models.

Another key aspect of Simio’s data-centric framework is the mapping of relational data tables to Simio modeling objects. Simio provides a hierarchical repeat group of object properties that can directly map to relational data tables. This unique and core concept in Simio makes it straightforward to map model properties to the required data.

Because the data that is used to generate or drive a model is typically in third party systems such as ERP, MES, IoT, Excel, CSV, or Web Services, Simio provides direct connectors for import and export to these common data sources. Additionally, Simio provides a framework for developing new data connectors. These data connectors are used to pull data from various data sources and into Simio’s in-memory relational data sets for quick access by the model. The use of Simio’s in-memory relational data set is critical to support fast execution and maintenance of the Digital Twin model.

4. Experimentation, Optimization, and Reporting

The purpose of a simulation model is to predict the performance of a new or existing system. In the case of design applications, proposed changes to an existing system or design options for a new system that does not yet exist are often evaluated. In the case of an operational process Digital Twin, the user may be interested in predicting operational performance, or in the case of a production schedule, prescribing or orchestrating actions to be taken in the real system.

Simio’s Digital Twin framework distinguishes between the concept of a simulation run with random processes and random events enabled, and a plan run where time durations are assigned their expected value, and all random events are disabled. Hence a plan run is deterministic and repeatable, whereas a simulation run produces different results for each replication of the model. A simulation or plan run can also be executed in actual clock time to support real-time integration and orchestration of an external system.

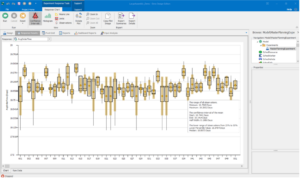

Simio’s experimentation and reporting features allow the definition of specific scenarios to execute simulation runs and then compare the results across the scenarios. Each scenario defines the value for one or more changeable inputs (such as the buffer size in front of each workstation) and one or more response variables (e.g., the average completion time of an order). Simio also provides the OptQuest optimizer that will automatically vary the scenario inputs to minimize or maximize a specified objective function. Experimentation can be done as part of system design, or off-line as part of system operations. The following shows an experiment comparing scenarios using SMORE plots, which graphically depict the mean, confidence interval for the mean, upper and lower percentile values, and range of each response variable.

Figure 5: Experimentation Results – SMORE Plots

In the case of design applications, summary statistics are provided, such as the average daily production or the average/maximum waiting time for customers visiting a health clinic. Simio provides a rich set of features for recording and displaying summary statistics on system performance, including confidence intervals and automated ranking and selection procedures.

In the case of operations with a process Digital Twin, users are typically interested in the detailed results for individual items such as a production order, machine, or worker. Hence, in addition to summary statistics, Simio also records detailed information in data logs that can then be used in report generation. For example, changes that occur for each material as well as the jobs that are processed on each resource are logged and can be used in custom reports and dashboards.

The Simio results can be shown in several different internal formats and exported to external reporting tools such as Tableau, Power BI, and Excel. One powerful internal format is Simio’s customizable dashboards that can be viewed both on desktop and a web browser using Simio’s Portal. The following is an example Simio dashboard.

Figure 6: Example Dynamic Results Dashboard

In the case of production planning and scheduling applications, Simio provides two different Gantt Chart-type displays that are particularly useful. The first is a Resource Gantt that displays resource status along a timeline for each enabled resource. Any row of the Resource Gantt can be expanded to show each entity/order being processed on that resource. The Entity Gantt chart shows each active entity/order in the system displayed on each resource that it utilizes during processing.

The Entity Gantt chart also shows risk measures for each job based on stochastic replications of the schedule in terms of the probability that the order will ship on time given the underlying variability in the system. Each row in the Entity Gantt can be expanded to graphically view all constraints that delayed the entity, for example, busy operators, unavailable materials, or other constraints, providing a root cause analysis for tardy jobs. The following is a sample of an Entity Gantt.

Figure 7: Example Gantt Chart Showing Detail Tasks

Simio makes it easy to toggle between the Resource Gants and Entity Gantts. Right clicking on any entity/resource on the Gantt chart provides the ability to run to that point in simulated time in the 3D animation of the system, moving to the graphical animation of the system state at that point in the schedule.

5. Intelligent Decision Logic

As simulation models move from predictive design applications to prescriptive operational Digital Twins, the precise decision logic in the model becomes more critical as it drives the performance of the model, and therefore the real system. Although custom built decision logic can produce good results, the use of neural networks is the gold standard since they can consider many more inputs and complex interactions to better optimize system performance.

With Simio, complex model decision logic can be replaced with self-trained neural networks. The neural networks provide complex decision logic in the model, and in return the model generates the required synthetic data to train the neural networks. This lets users simplify the model’s decision logic, which makes models easier to build, understand, debug, and maintain. With neural networks, the focus can be on modeling system components, while allowing the neural networks to learn the complex relationships to optimize decision making within the model.

Simio is the first and only discrete event simulation software to provide comprehensive AI features for creating and auto training neural networks in a model without requiring programming or the need to integrate with external 3rd party tools.

One of the major challenges of AI is having the required labeled training data and many AI applications fail as a result. Labeled training data is never available when evaluating a new system and even in cases with existing facilities, any recorded data becomes invalid once a new part or change in flow is introduced to the system. That’s why Simio’s built-in auto-labeler for creating synthetic training data is critical to the success of an intelligent modeling application.

Simio also provides integrated training algorithms for training neural networks using synthetic data that is generated by a model. Hence Simio provides a complete solution for embedding neural networks in simulation models.

Simio’s AI features are particularly useful in production planning Digital Twin applications where the neural network can be trained to predict critical KPIs, such as the dynamically changing production lead time for a factory or production line within a factory. The neural network learns the impact of changeovers, secondary resources, business rules, and other production complexities that impact the prediction of the KPIs. The intelligent Digital Twin can capture complex relationships that would otherwise be impossible to include in a model. The neural network KPI predictions can then be used to better optimize decisions both within the factory and across the supply chain. Within the supply chain, the neural network can be used for the critical supplier sourcing decision by predicting the production lead time for each candidate supplier and selecting the lowest cost producer that can complete the order on time. AI-based factory sourcing within the supply chain Digital Twin eliminates the need for Master Production Scheduling software that employs a rough-cut capacity model but ignores production constraints such as changeovers, assumes fixed lead times regardless of factory loading, and schedules into artificial time buckets using a heuristic algorithm. This results in roughcut and non-actionable schedules that take many hours of computer time to produce and don’t align with the detailed factory schedules.

Simio’s built-in AI features provide support for defining, training, and using the classic feed forward regression neural network. However, users are not limited to this machine learning algorithm since any machine learning regression model from over 50 third parties, including Google and Microsoft, that support the ONNX model exchange format can be imported and used within Simio. Users can build and train models in third-party tools and then import them to Simio for complex decision making within a model.

Figure 8: Using Third Party ONNX Models

6. Enterprise Deployment

Simulation design applications have traditionally been deployed on the desktop. Although the desktop environment provides a generally richer user-interface for the model building phase of a project, the deployment of enterprise applications with multiple simultaneous users with different roles and data permissions requires a more secure/robust environment. Although Simio desktop remains the best option for model development, Simio’s Portal provides a better solution for both experimentation and executing and viewing results and operational plans.

Simio Portal democratizes simulation and scheduling results over the web to users across the enterprise. Modelers can manage users and assign roles that limit their access to models and data. Simio Portal can be hosted within an on-premises data center, or respective Azure, AWS, or Google cloud tenant, allowing users to create and execute simulation experiments and scheduling plans with unmatched speed. Models can be built using desktop Simio and then seamlessly deployed onto Simio Portal.

Figure 9: Simio Cloud Deployment

7. Summary

Simio provides a simulation modeling framework based on intelligent objects to optimize both the design and operation of complex systems. Simio’s key features that support the design through operation continuum include the code-free object-oriented modeling architecture, data- centric framework to support both data-driven and data-generated models, simulation and scheduling experimentation and reporting features, neural networks to optimize decisions, and enterprise deployment options for experimentation and scheduling on private and public clouds. Simio provides a comprehensive simulation platform for a complete digital transformation journey.