Simio Solutions for Streamlined Operations & Superior Performance

Innovative technologies for dynamic simulation, planning, and optimization of digital twins.

Why Simio?

Simio provides comprehensive solutions designed to address unique challenges through Digital Twin models that accurately replicate real-world operational processes and integrate effortlessly with enterprise data and systems. With tools and methodologies ranging from discrete event simulation to advanced planning and scheduling, and demand-driven digital twin software, Simio provides businesses with the operational agility to thrive in volatile and complex environments. Explore our solutions below to optimize your decision-making processes and enhance overall performance.

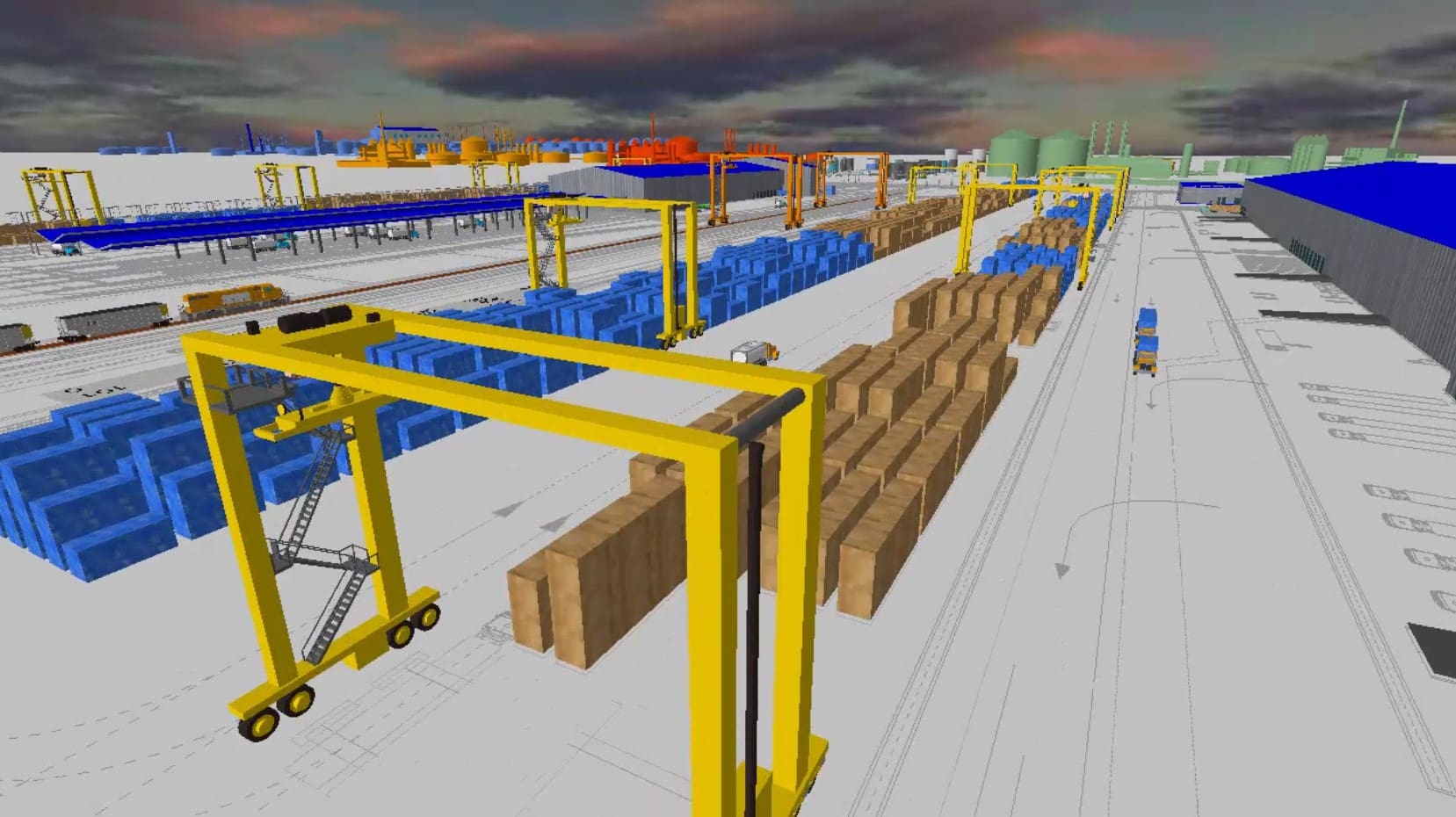

Simio Discrete Event Simulation Software

Simio Discrete Event Simulation (DES) Software is a powerful tool for analyzing, designing, and improving complex systems and processes. By enabling users to model and visualize intricate workflows, Simio DES provides actionable insights into variability, constraints, and optimization opportunities. This technology plays a pivotal role in a broad spectrum of industries, helping organizations make informed decisions and mitigate risks.

Key Benefits & Features

Simio DES enables organizations to continuously explore improvement opportunities that lead to lasting benefits.

Visualize and Analyze Systems:

- Simulate present or future behaviors of any system or process.

- Provide stakeholders with 3D models to foster understanding and confidence in solutions.

Evaluate Alternatives

- Predict the outcomes of layout changes, operational rules, or scheduling adjustments.

- Assess various configurations to support CapEx planning and reduce risks before implementation.

Optimize Performance

- Identify the best configurations for key performance indicators (KPI) through experimentation.

- Unlock continuous improvement opportunities with iterative simulations.

Accommodate Variation

- Incorporate variability such as supplier delays or equipment failures to ensure robust solutions.

- Simulate real-world randomness to evaluate process resilience and stability.

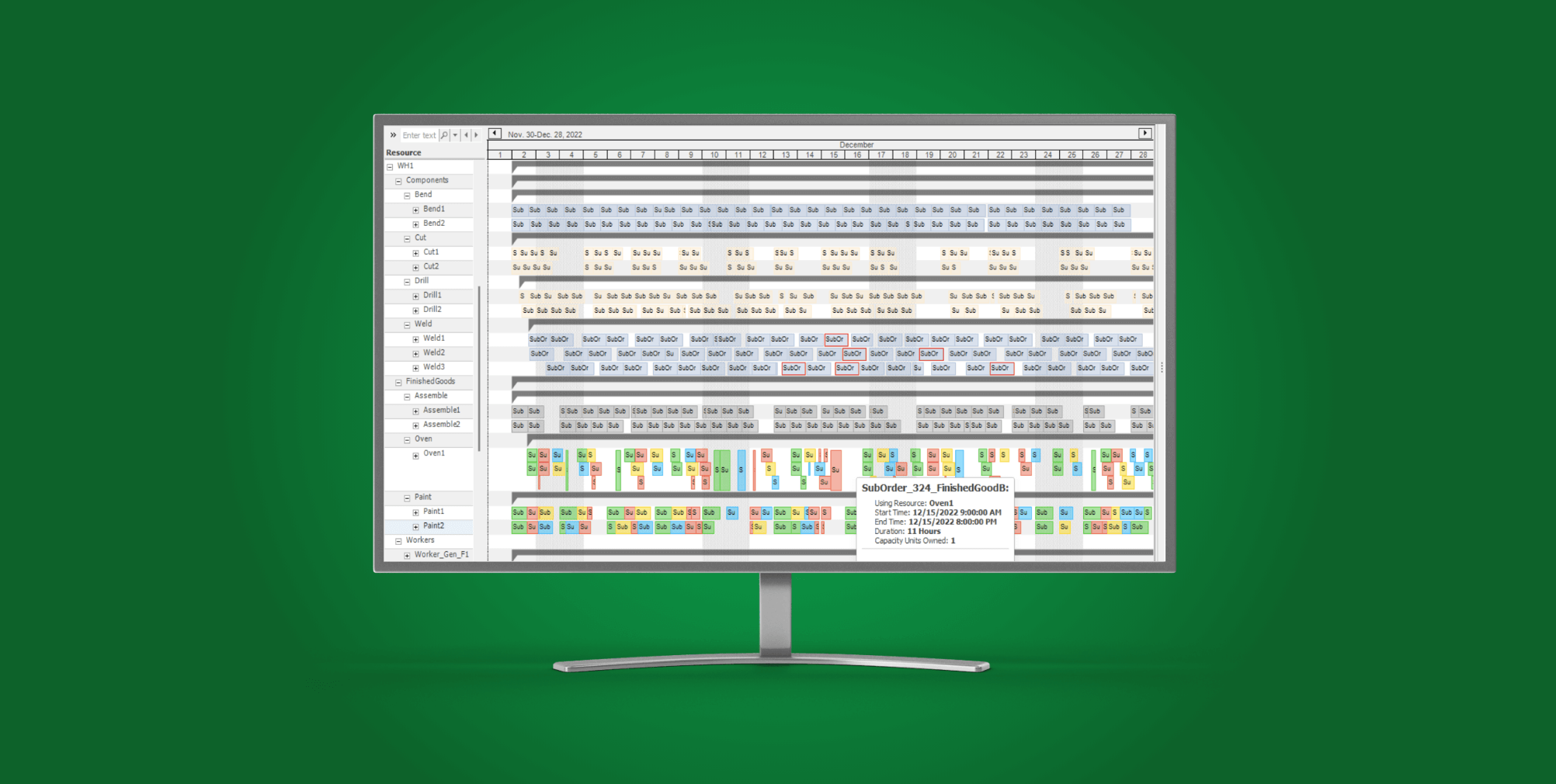

Simio Advanced Planning and Scheduling (APS) Software

Simio’s Advanced Planning and Scheduling (APS) Software revolutionizes traditional planning methods by using Digital Twin technology. This approach generates feasible and optimized production schedules that are synchronized across resources, materials, and timeframes, enabling agile responses to unplanned disruptions.

Key Benefits & Features

Simio APS helps businesses deliver on commitments, increase efficiency, and achieve operational excellence.

Synchronized, Feasible Schedules

- Integrate with existing processes to ensure material, resource, and timeline feasibility.

- Avoid missed deliveries and reduce downtime with predictive scheduling capabilities.

Dynamic and Responsive Planning

- Adapt to real-time events, such as machine breakdowns or shifting customer priorities.

- Provide actionable insights that help businesses respond effectively to unexpected challenges.

Powerful Visualization Tools

- Utilize Gantt charts and tailored dashboards for detailed schedule insights.

- Visualize real-time resource usage, bottlenecks, and optimization scenarios.

AI & Advanced Features

- Leverage machine learning and AI for smart resource management and optimal schedule generation.

- Conduct extensive what-if analyses to design and deploy data-driven strategies.

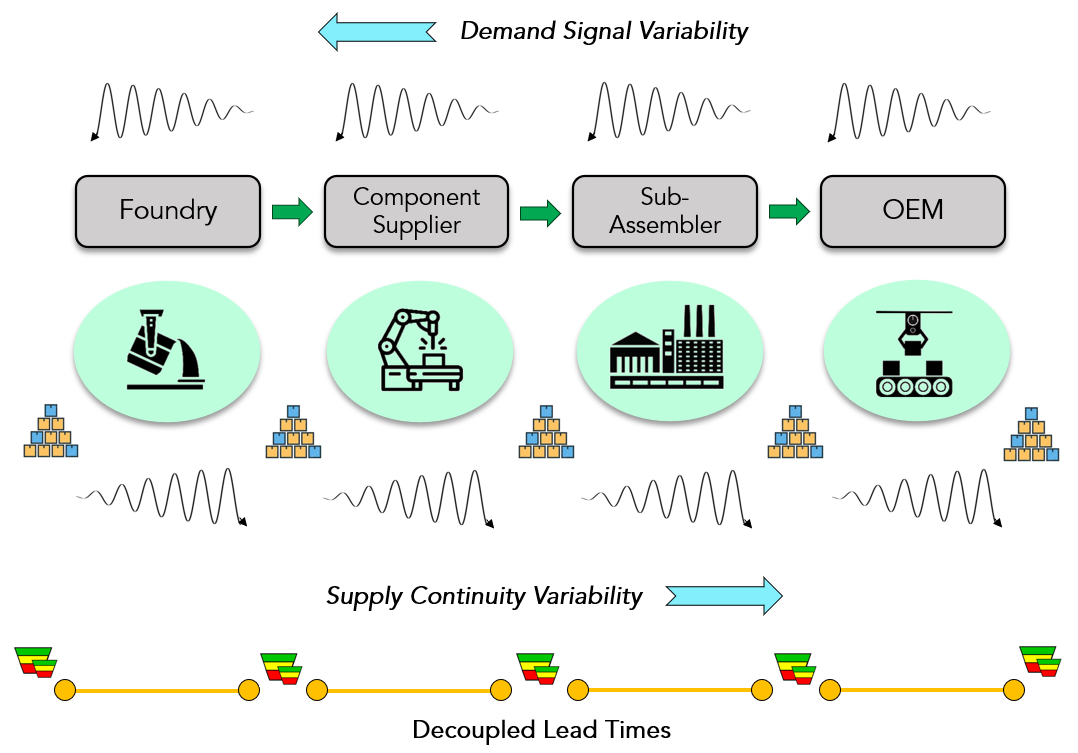

Demand-Driven Digital Twin Software (DDMRP)

Certified by the Demand Driven Institute, Simio merges DDMRP principles with adaptive Process Digital Twin technology for unparalleled inventory and supply chain management. Simio’s solution ensures that organizations can dynamically plan and execute strategies to meet demand while minimizing waste and variability.

Key Benefits & Features

Simio’s DDMRP solution addresses today’s supply chain challenges with precision, visibility, and clarity.

Demand-Based Planning

- Protect product flow by positioning buffer stocks at strategic points.

- Reduce the bullwhip effect by focusing on relevant, real-time demand signals.

Customizable Models

- Simio’s templates allow for rapid model creation and adaptation to various requirements.

- Incorporate decision logic and constraints to reflect real-world supply chain processes.

Actionable Insights

- Use forward-looking dashboards to evaluate stock levels, order performance, and resource utilization.

- Identify key constraints affecting processing flow or material delivery.

End-to-End Optimization

- Simulate complete manufacturing and distribution networks to design competitive, responsive systems.

- Evaluate ROI, process efficiency, and customer satisfaction impacts.