Disruptive change need not come at the expense of conventional or existing operational models. An excellent example that highlights the above statement is the widespread adoption of digitization in the manufacturing industry. Replacing paper and physical items with their digital counterpart eased the storage of historical data sets and simplified analytics by working alongside legacy systems. Thus, the increased adoption rate of artificial neural networks is set to ease the application of industry 4.0 business models in manufacturing.

Industry 4.0 creates diverse opportunities for enterprises to leverage advanced technologies to optimize operational processes. Technologies that enhance digital connectivity, support the development of cyber-physical systems, drive analytics, and automation is crucial to the application of Industry 4.0. Artificial neural networks or neural networks empower digital systems and AI applications with the ability to function intelligently without human intervention.

What are Neural Networks? A brief description

Neural networks are a subset of AI and are crucial to the application of deep learning algorithms. Neural network algorithms reflect the behavioral patterns of the human brain. Integrating neural networks within computer programs and systems empower them with the ability to recognize patterns and analyze data to solve problems.

Neural networks are algorithms commonly used in a variety of applications including regression models for predicting values, analyzing text/speech, recognizing/classifying images, anomaly detection, and pattern recognition. A neural network consists of an input node, hidden nodes, and an output node. The input node takes in data; the hidden node is where the computation happens to provide a predicted output at the output node.

Getting Started with Neural Networks in Industry 4.0

Integrating neural networks starts with analyzing industry 4.0 business models and the technologies required to implement them and then determining how they can be enhanced. These business models include predictive maintenance, data-driven plant or process optimization, validation and testing etc.

Enhancing Predictive Maintenance Applications

One of the Industry 4.0 business models that have reduced the cost of utilizing manufacturing equipment is the application of predictive maintenance models to plan schedules and eliminate downtime. Predictive maintenance strategies are implemented by capturing machine utilization data and analyzing this historical data to predict future breakdowns.

Today, web and mobile applications that analyze the data required to predict maintenance timelines exist. Although these applications have reduced machine failure by approximately 70%, more can still be accomplished by integrating neural network algorithms into predictive maintenance applications. Neural networks can enhance the application of predictive maintenance by automating the data analytical process and improving prediction accuracy.

ANN enhances the predictive process by providing insight into the causation factors of failures, the specific timeline of expected failures, and the best time to conduct inspections. The predictions neural networks provide enable enterprises to implement proactive maintenance systems that may reduce failure rates by 90%.

Enhancing the Application of Data-driven Optimization Models

Data-driven analytics improve the decision making that occurs within a facility. For example, capacity planning or scheduling technician work cycles ensure a facility has the resources to execute jobs within specific timelines. Conventional simulation modeling software can be used to develop optimized plans that leverage historical datasets. But in scenarios where complex questions such as; ‘choosing the fastest production line between two lines affected by multiple operational factors’ must be answered, more computational resources are required. Examples of operational factors could include sequence dependent setup times, resource availability, and the type of work may affect the make span of each line.

Although a simulation model of this complex process can be built. The man-hours required to develop the complex logic that captures every factor affecting both production lines is considerable. Neural networks provide a faster, automated solution to developing the rules or logic to solve the complex problem of choosing the faster make span from two production lines. In this case, a neural network replaces the need to spend weeks developing a complex logic and automates the data-driven decision-making process.

Other sectors where neural networks enhance data-driven optimization business models include providing insight into complex supply chain operations and predicting the effects of demand on available resources. Here, neural networks can be integrated into supply chain planning software, simulation modeling, or demand forecasting software to speed up the analytical process.

Validation and Testing

Approximately 70% of DIY IoT implementation processes fail due to the use of inadequate validation and testing techniques before deployment. Although this statistic focuses on IoT implementation, poor validation also affects the execution of production or operational plans across the industrial sector. This is why validation and testing is a core business model or concept of Industry 4.0.

Simulation models and the Digital Twin provide the digital transformative tools enterprises can employ to validate ideas before implementation. These solutions provide virtual representations of physical systems thus providing a safe environment for validating proposed operational strategies. Neural networks provide a means of enhancing the application capabilities of the aforementioned digital transformative tools and can also gain from the simulated environment the tools provide.

For example, neural networks can replace the complex logic needed to develop accurate models that produce highly-precise predictions concerning a strategies performance. Conversely, the simulation or digital twin model churns out training data that can be used to train the neural network to improve its predictive powers.

What is Holding Company’s Back from Leveraging Neural Networks

Adopting the use of neural networks to enhance industry 4.0 business models improve plans, increase productivity, and extends the life-span of operational equipment which ensure profitability. Despite these benefits, enterprises in the industrial sector remain wary of biting off more than they can chew. Reasons for this cautious approach to adopting neural networks include;

- Lack of the right talent and training

- Confusion concerning how to choose a solution from a plethora of digital solutions

- Short-term thinking to protect the status quo

The outlined reasons for caution are all valid as diverse digital transformative solutions that require a varying level of expertise to manage consistently vie for the attention of C-level executives. Unlike other solutions, where considerable efforts are required for a successful deployment, neural networks can be integrated with ease.

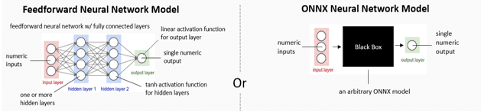

Solutions such as Simio simulation and digital twin modeling software integrate the use of feedforward neural networks and users can take advantage of it without any coding experience. End-users can also leverage Simio to develop synthetic training data to train their neural network algorithms. Lastly, ONNX provides users with an open source file format for transferring algorithms across diverse applications with ease.

Organizations can take advantage of neural network by leveraging the right technology that supports its use and empowers you to achieve your operational goals. By investing in these technological solutions, leaders can prepare for the operational challenges of tomorrow while managing today’s challenges.