by Dusan Sormaz and Mandvi Malik (Ohio University)

As presented at the 2017 Winter Simulation Conference

Abstract

Order picking is the most expensive operation in a distribution center. Due to a large amount of labor used in order picking, the cost associated with the labor is high. The objective of this paper is to build a simulation model that would help distribution center managers to forecast their throughput by optimizing the worker configuration. The research uses a hierarchical approach to build a simulation model. The simulation model is divided into small submodels. The submodels are completely independent of each other. The submodels can be combined to make various different complete models. In this research, the submodels are used to build a simulation model of an actual industrial distribution center. The model is then run for twenty-four hours and the results are compared with the flat simulation model of the same distribution center.

Introduction

Simulation has become a potent technique used by supply chain companies as a decision support tool [1]. There are many benefits of simulation in supply chain as it can help in identifying the bottleneck and performing experiments to minimize the risk of changes [2]. The objective of this research is to build a simulation model that can be reused to make various different distribution center models. The model is built using Simio [3].

There are two approaches to solve a problem in Simio. The first approach is to make a model in which entity flow logic is done separately for each object and repeated for each similr object. This model is called flat simulation model using standard objects. A second approach is a hierarchical approach that is to divide the problem into several small subproblems. In hierarchical approach, a library of submodels is created. The submodels are used as objects to create a comprehensive model. The submodels can be reused to make another model. The present paper uses hierarchical approach. The benefits of creating a simulation model using hierarchical approach over flat simulation model are following [4]:

- All the options to solve a problem can be included which is not possible in a flat simulation model,

- The validation and verification are done faster and they are more reliable since the logic would be tested at small submodel levels,

- Modifications of the model are done faster,

- Through multiple models and different approaches to the model design, we can eventually build better models in the future.

For our study, applying the hierarchical approach allows the following benefits:

- Low level model can be reused for different distribution center configurations,

- Component models can be used for other order arrival policies,

- Verification of component models individually enables faster model development.

Methodology

In order to make simulation model of the distribution center, the first step is to make potential submodels for the picking operations in a distribution center. This research focuses on the zone picking strategy. In zone picking strategy a worker is assigned to a zone and picks up items from his/her zone. An order may have items in multiple zones. The assumption used in designing the model is that distribution center is divided into multiple zones. There are levels in the distribution center which contain multiple zones. There are towers that are made up of multiple levels. A tote with labelled barcode would come to a tower only if there are items to be picked from that tower. The order picking is done in the zones by the workers. There are conveyors to move tote from one location to another in the distribution center.

The potential submodels created are zone, level, tower, mezzanine, shipping and arrival submodel. This paper describes basic submodels. These are defined below:

- Zone Submodel: A two-sided zone submodel is created using two servers. The logic defined in the zone submodel is that a tote would be directed to a zone from central conveyor if there are items to be picked from that zone. The totes are modelled as parent entity that carries individual ordered items, and each item has properties that define its location in the distribution center. The following properties were created: zone location, picking time and zone workers. The picking time and the worker property would be defined in the complete model.

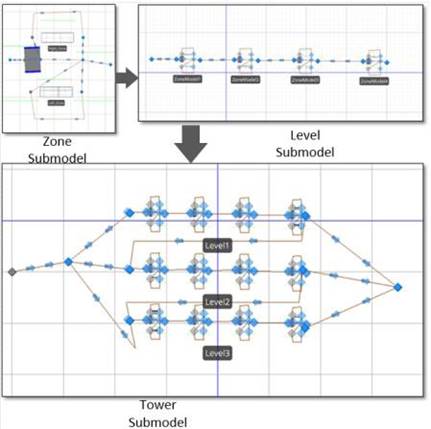

- Level Submodel: A level submodel is built by combining multiple zone submodels. This model inherits all the properties of zone submodel. The zone location property is defined here, this property would provide an identification number to a zone in a level.

- Tower Submodel: A tower submodel is created by combining multiple levels. The level location defined here is same as the zone location. The logic of a tote to come to a level in a tower is defined in this model. A tower location property is created. Figure 1 shows steps to build a tower submodel.

- Picking Tower Submodel: A picking tower submodel is created by combining multiple towers. The logic of unit/tote to come enter a tower is defined in this model. The tower location property is also defined in this model.

- Arrival Model: The arrival model is created to model the assignment of orders to totes. It defines the number of items in a tote, using an empirical distribution, and policy of ranking picking order of items. This model is usually configured by historical data. Those models are built into the top level model shown in Figure 2 and explained in the next section.

|

|

CASE STUDY

After creating the submodels, a complete simulation model of a distribution center located in Columbus, Ohio was made (Figure 2). A flat simulation has been made by Sormaz et. al [5] for the same distribution center. The distribution center has three towers. Each tower has three levels and each level has eight zones. There is also a mezzanine with six zones. The complete simulation was made by combining the picking tower, mezzanine, shipping tower and the arrival submodels. The properties that were defined in this model are picking time, number of workers, and packing time.

RESULTS

The hierarchical model was run for twenty-four hours and the results were compared with the flat simulation model from [5] of the same distribution center. Table 1 presents the results of the flat simulation model and hierarchical model. The results are comparable. Hence, the model is valid.

Table 1: Simulation results of flat simulation model and hierarchical simulation model (HM)

Experiment |

Tower Workers |

Mezzanine Workers |

Average Throughput [5] |

Average Throughput (HM) |

1 |

48 |

15 |

151,026 |

151,863 |

2 |

30 |

10 |

150,915 |

151,874 |

3 |

35 |

11 |

150,802 |

150,191 |

4 |

40 |

12 |

151,173 |

151,079 |

5 |

55 |

18 |

150,515 |

150,749 |

CONCLUSION

The presented hierarchal model would help distribution center personnel to forecast their throughput by configuring the worker population. Building component models allowed for easier model logic verification since each submodel was independently tested before using in thr gighr level model. The simulation model is currently limited to picking operation and the future work of the model would include other operations of the distribution center. Building a hierarchical model reduced the model implementation time by 40%.